A New Skin for Old Residences

The latest Steligence® study examines over-cladding options for Deep Energy Retrofits

Story: Ian VanDuzer

Photography: Sandra Mulder & Morgan Rice, Graphics by Michelle Hayward

You will find them in every city: concrete high-rises standing taller than 8 storeys. Built between 1960 and 1990, these concrete complexes serve as the backbone of most of our cities, representing a first real strive to build residences up instead of out.

Today, owners of these buildings are faced with a choice. Due to rising energy costs – and greater calls to be more energy efficient by both public and government – many owners are looking for ways to drastically improve their building’s performance while also resulting in a positive return on investment.

It’s this practical application that makes elements of a deep energy retrofit so applicable to a Steligence® study, says Matthew Winters, a Projects Manager for ArcelorMittal Dofasco’s Steligence® initiative. “When we plan for our next study, we look at things that architects and engineers will use,” he explains. “We want to engage with current trends in the construction industry.”

The latest Steligence® study, published last November, is a perfect example of this, examining various different over-cladding solutions as part of a deep energy retrofit.

Getting (Skin) Deep

A deep energy retrofit is a holistic approach to improving a building to make it significantly more energy efficient. Typically, deep energy retrofits have a target of 50% increased efficiency over the baseline. There are many different aspects of a deep energy retrofit but, as illustrated by the concept of Passive House design, the building’s facade has an incredible amount to do with both keeping heat in, and keeping the cold out.

Enter over-cladding, the approach of “re-skinning” an existing building with an outer shell of material, meant to significantly reduce heating loss while creating minimal disruptions to the building itself. Over-cladding itself is not a new process, but a greater emphasis on retrofitting older buildings prompted a new Steligence® study on various established and emerging methods over over-cladding.

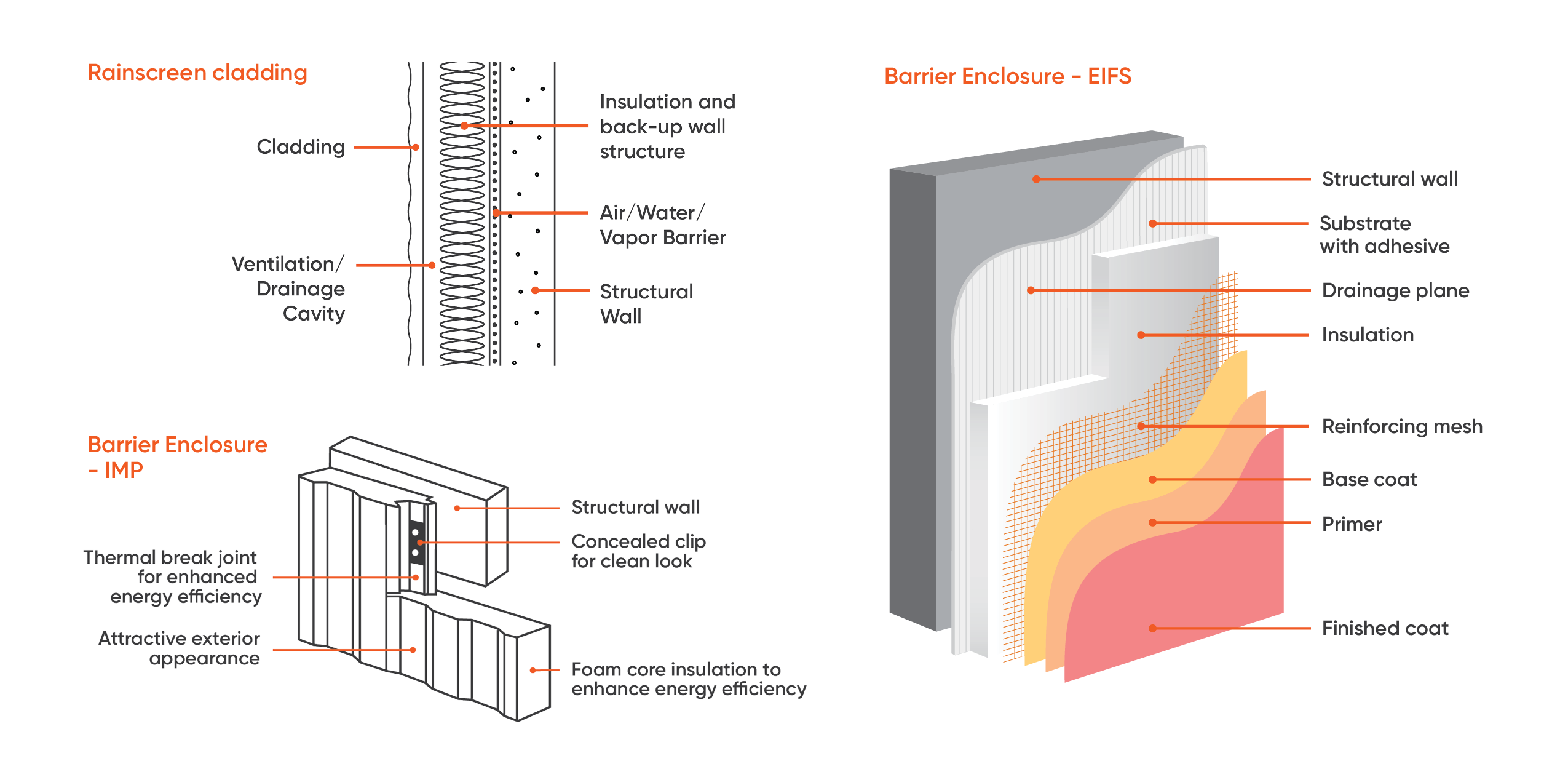

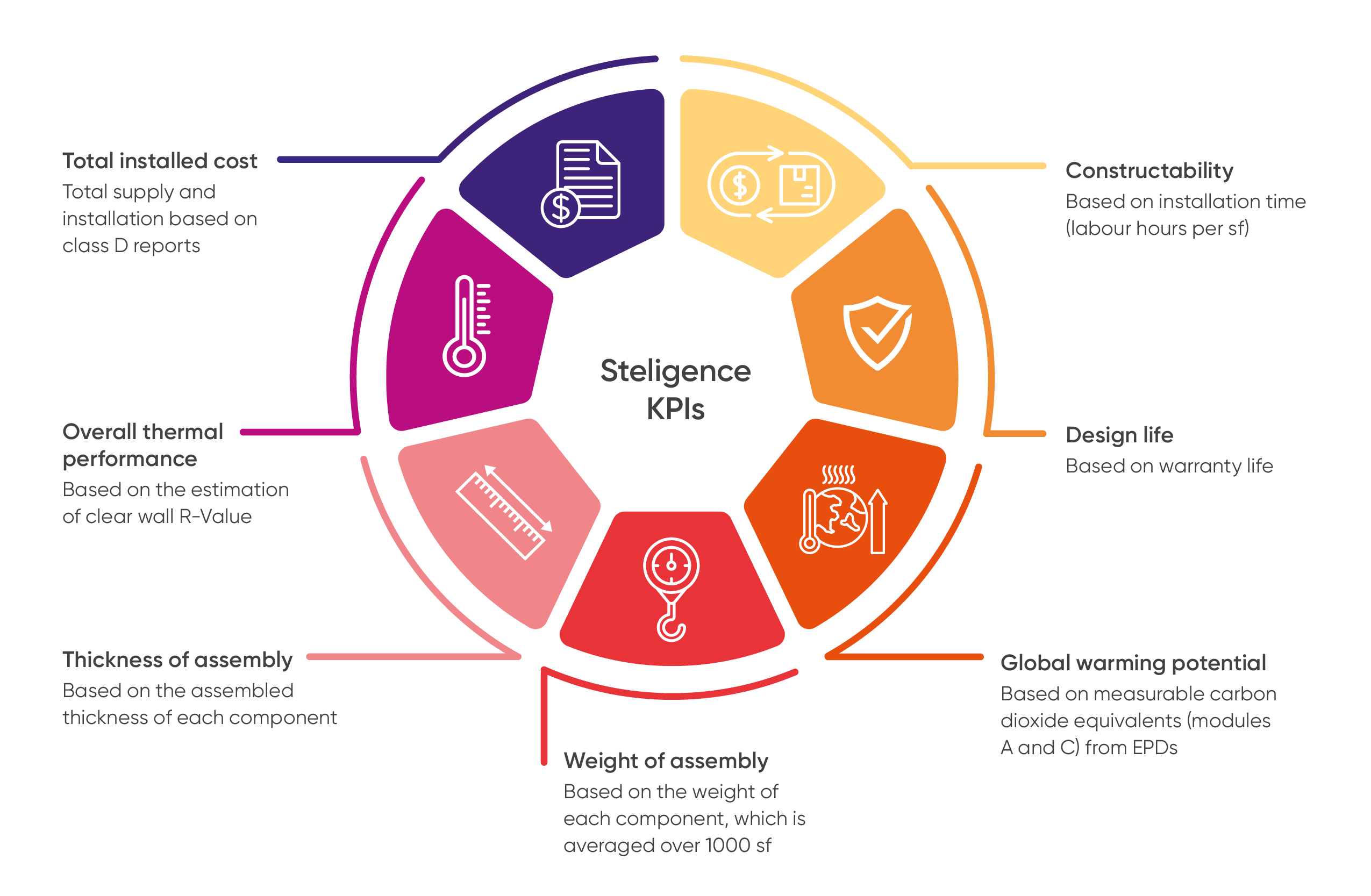

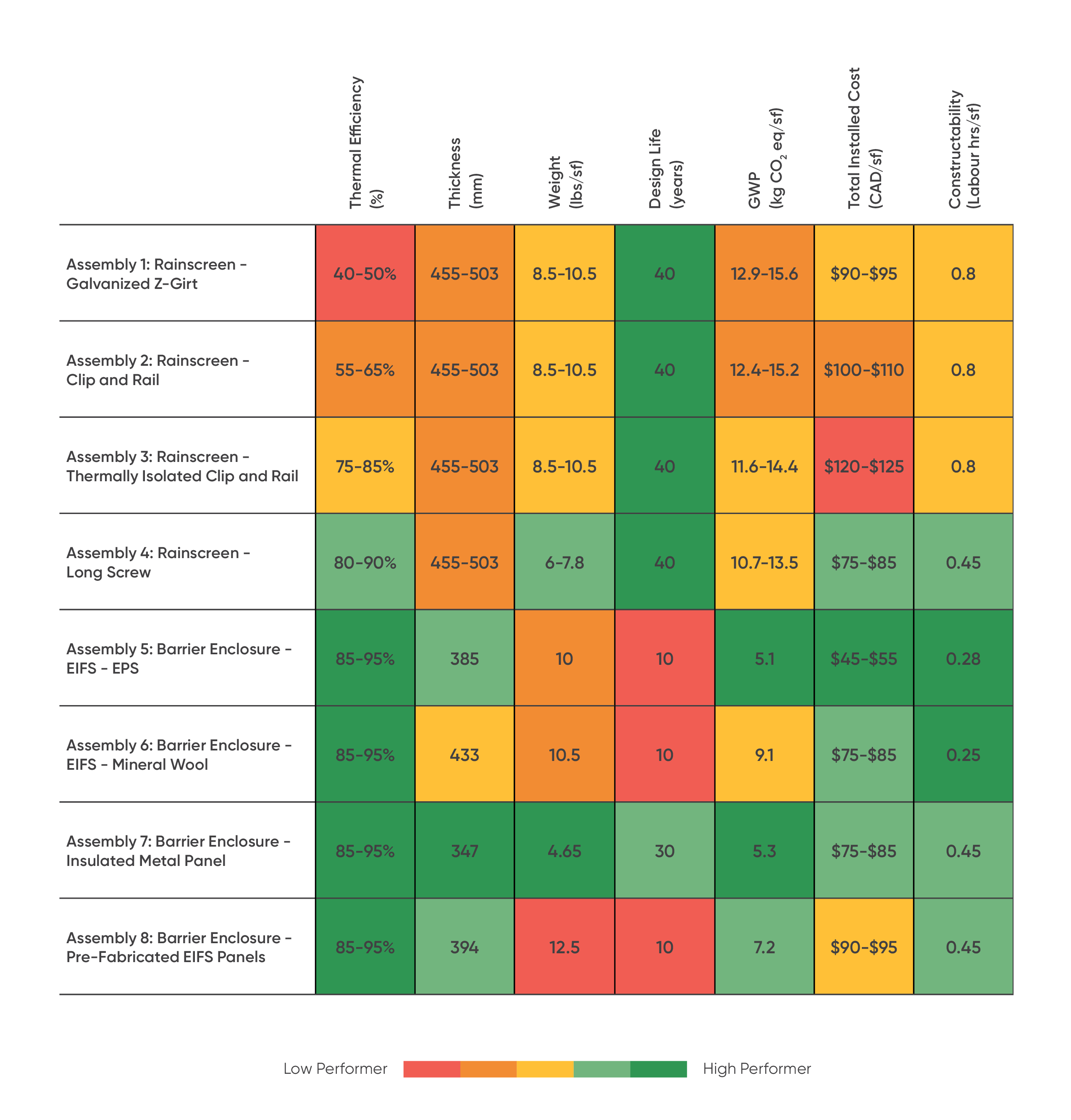

The study quantified eight over-cladding assemblies as they pertained to high-rise concrete buildings built between 1960 and 1990, of at least 8 storeys tall, and having at least 60 residential units. The assemblies are broadly broken down into two categories: rainscreens and barrier enclosures. Each assembly was judged on seven identified KPIs: total installed cost, overall thermal performance, thickness of assembly, weight of assembly, design life, global warming potential, and constructability.

Why these Choices?

Before diving into the study results, Winters shared some thoughts on why these specific parameters were chosen for the Steligence® study. “With over-cladding, you’re putting on a new skin over an existing wall. That makes the building heavier,” he explains. “So, you need a building with a good amount of meat on its bones already in order to accept that additional weight without causing any structural problems.”

There was another factor to consider: retrofits are, by definition, difficult to generalize. “There’s no such thing as cookie-cutter,” Winters points out. “So, it's just trying to understand some of those niche scenarios, and help recommend solutions that may make sense on a case by case basis.”

However, despite the specifics, Winters believes that a study like this is crucially important. “In order for Canada as a country to achieve its decarbonization goals, we can't just look at new buildings,” he says. “There are so many existing buildings that are due for upgrades, and you're going to save so much embodied carbon by retrofitting these buildings as opposed to tearing it down and building something brand new in the same spot.”

Digging Deeper into the Results

What is immediately clear upon looking at the quantified results table is that there is no clear “winner” to the question of what is the best assembly to use while over-cladding. “We stayed away from making a definite conclusion, because architects and engineers are going to determine what their priorities are,” says Winters.

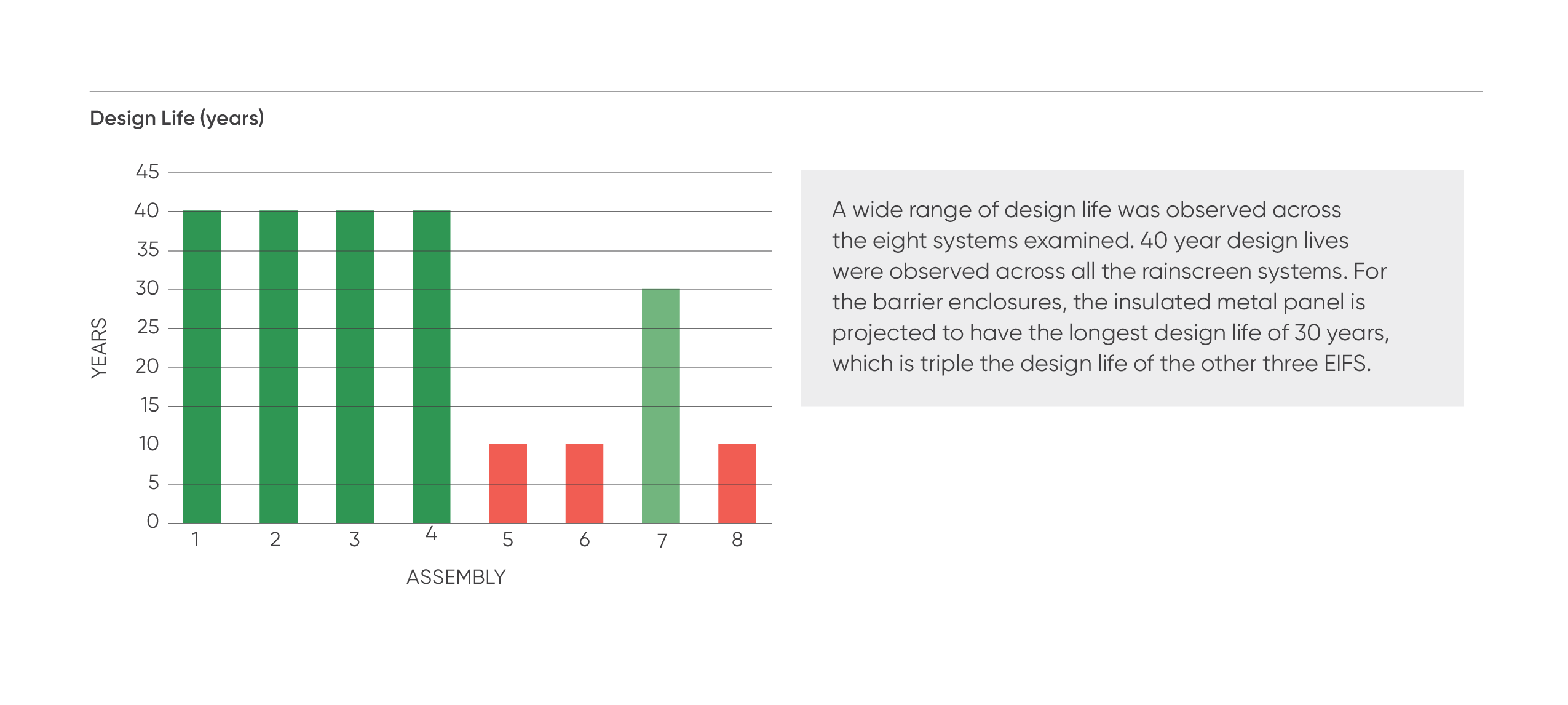

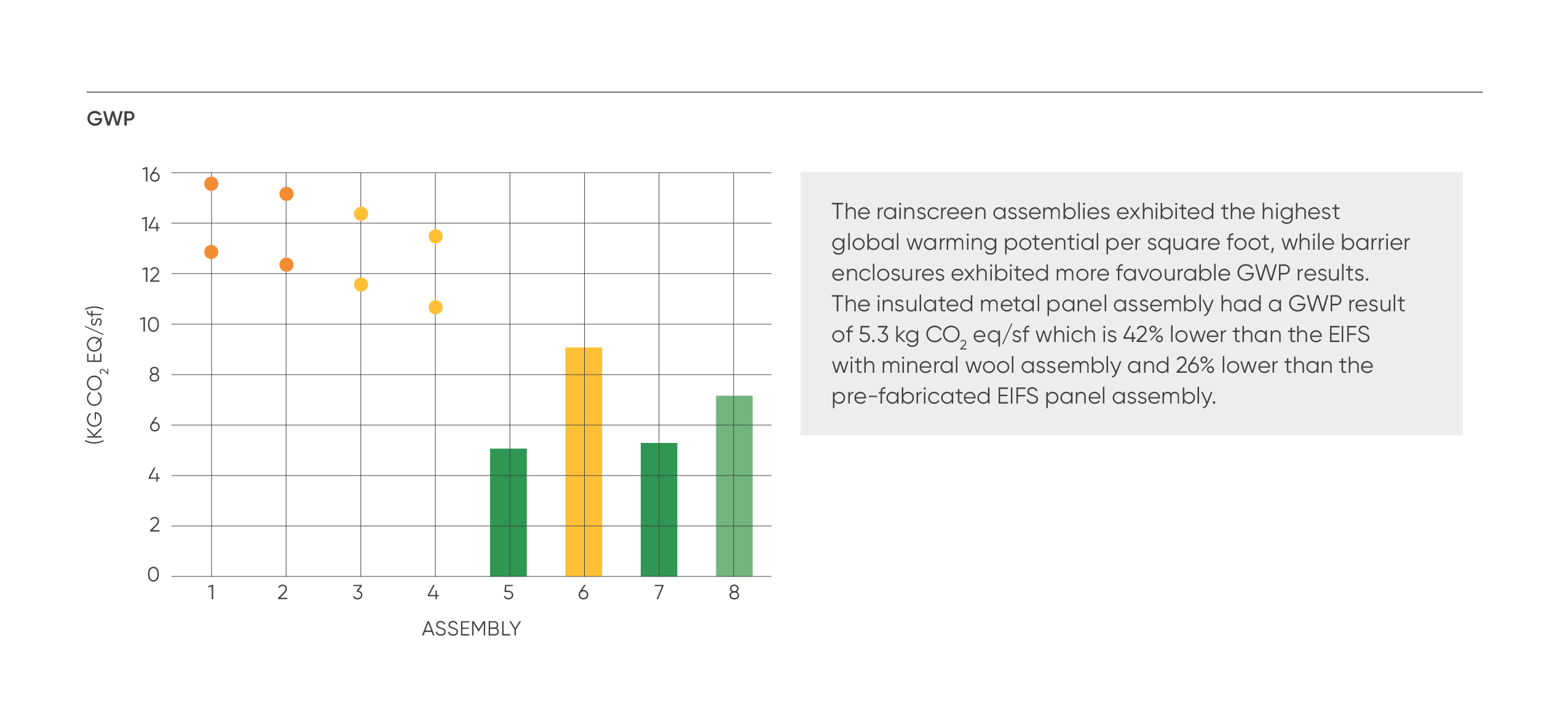

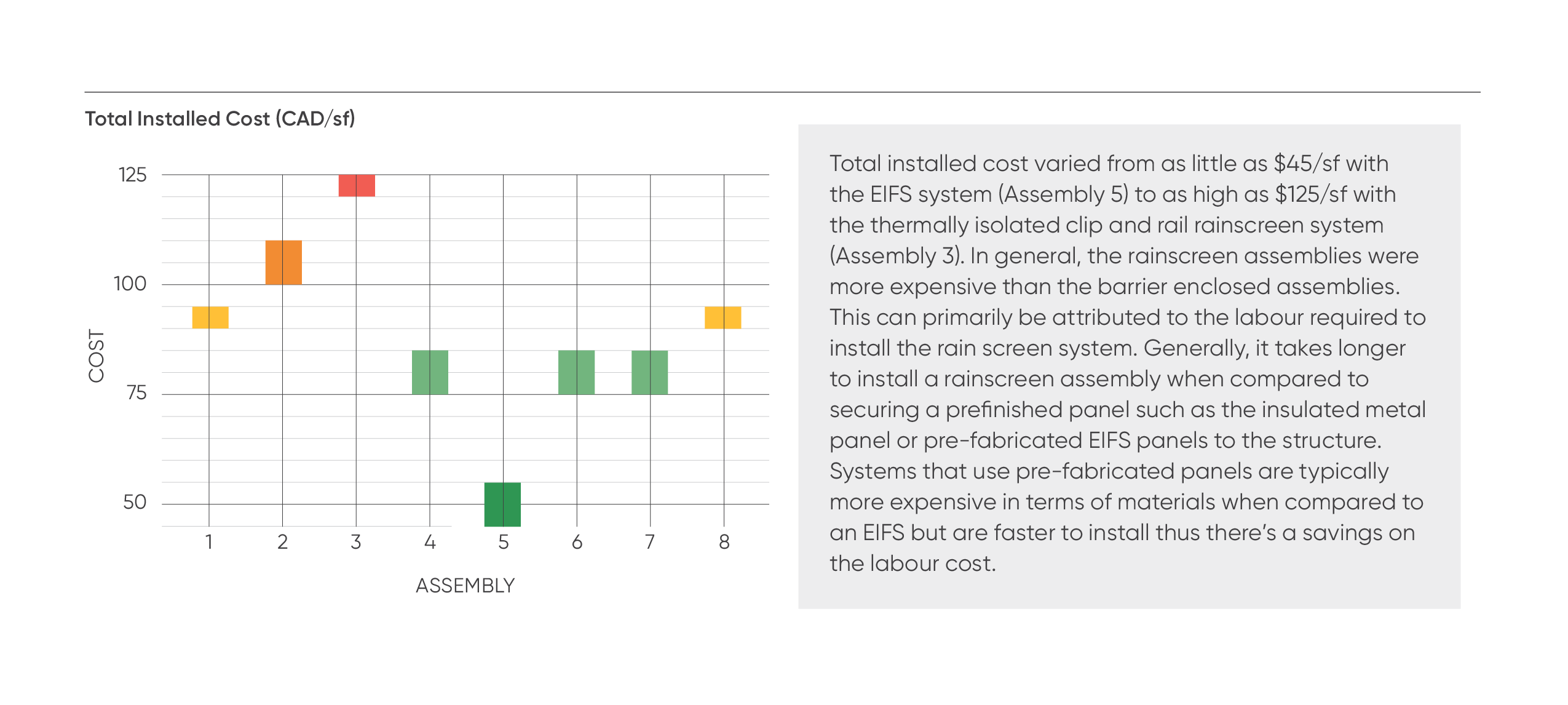

Some of the rainscreen systems are lacking in thermal performance, but shine in terms of design life (forty years). Meanwhile, the industry-standard EIFS assemblies perform moderately well across all metrics aside from design life (10 years) and weight. For the purposes of this study, design life was defined as the warranted life of the system.

And then there is the IMP assembly, which is well-rounded: presenting a middle-of-the-road cost along with excellent thermal efficiency and thickness. “It’s fair to say that assembly 7 (Barrier Enclosure - IMP) doesn’t perform the best in every individual metric,” Winters agrees. “It's not the cheapest. It doesn't have the longest design life. But when you're looking at everything kind of holistically, it seems to perform quite well, and there's very few metrics where it falls down, which is not necessarily the case for the other systems.”

All of this, again, is up to interpretation – and prioritization. “You may have a project where the only consideration is cost,” Winters says. “That would lead you towards an EIFS system over a rainscreen.”

Or, there may be considerations outside of the seven selected KPIs that influence decision making. “How do you quantify aesthetics?” Winters laughs. “I think that’s the biggest advantage of a rainscreen system: you have a lot more options to choose from for your cladding, so you can reenvision your building in a really striking way.

“But that doesn’t necessarily come through in the study.”

Providing the Data

Winters reiterates that the purpose of Steligence® is not to definitively prove that one system is superior over another. “We’re trying to provide that foundational baseline of information that industry professionals can interpret and make their own decisions,” Winters says.

“For over-cladding, EIFS is the industry standard. And looking at the results, it’s understandable: it's thermally efficient with a very low installed cost,” he says. “Those are most often going to be, two of your key performance metrics, the ones that everyone's going to look at the most,”

But Winters also pointed to places where EIFS may fall short in the rankings, specifically weight and design life. “For those applications, the steel assemblies really shine,” he identifies. Add on steel’s inherent flexibility, recyclability, longer warranties, and – especially in the case of the IMP assembly – equal or better thermal efficiency, and you have a real reason to consider steel products over the industry standard for a deep energy retrofit.

“There's definitely applications and scenarios where insulated panels do make more sense than the EIFS,” says Winters. “It’s all about supplying the data for informed decision making, so that architects, engineers, and building scientists can all make the decisions that are best for them.”

SPECIFICATIONS

Steligence Deep Energy Retrofit: Over-cladding Case Study

DESIGN SCENARIOS:

McCallumSather Architects was the external partner that contributed

to this case study and conducted the wall assembly development

and assessment.