Inside Steligence®

Engineers and architects talk about the value of data-driven science in the built environment

Story: Ian VanDuzer

Photography: Sandra Mulder & MTE Consultants Inc.

It was a Tuesday morning at the Canadian Steel Conference, and most of the attendants of the panel were still holding paper cups of coffee from the hotel buffet. The session – titled CFS 12-storey building case study – took up the biggest session room at the conference, with seating for 240 people. And it was close to a packed house.

The panel was just one of the many ways ArcelorMittal has been promoting their Steligence® studies across North America. A global initiative that’s picking up steam in Canada and the United States, Steligence® seeks to fill a necessary gap in the construction industry; a gap that, if you listen to the panelists, is sorely missing."

Within certain sections of the construction industry, there’s not an openness about the benefits of materials,” explains Willems Ransom, a Principal Architect at mcCallumSather and one of the panelists of the Canadian Steel Conference panel. “That’s the role that Steligence® seeks to fill.

”While the panel was ostensibly about this particular case study – an examination of how different materials impacted the carbon footprint, cost, and construction time of a 12-storey apartment building –as the morning drew on, the panelists couldn’t help but let their enthusiasm for the Steligence® project bleed through.

Apples to Apples

Long-term readers of Steel Design will be no strangers to Steligence®: many past Steligence® studies have been featured as articles here. However, the importance and relevance of Steligence® goes beyond a single study or a single panel.

Steligence® was started by ArcelorMittal in Europe, but since location is such a crucial element of the studies, the steel producer established a North American version of the program in 2017. Since then, the North American Steligence® has published seven official case studies, with an eighth coming out in early. According to Michael Stiller, who heads the North American version of the program, ArcelorMittal has invested north of $1 million into the Steligence® program here in Canada and the United States.

While Steligence® exists to promote the use of steel in construction, the studies work hard to be objective looks into the benefits of different materials. “We work really hard to make everything transparent,” Stiller explains. “Sometimes, we get results that don’t favour steel, or don’t favour steel as much. But that data is just as important.

“The important thing is to create studies that can be used and relied on to be fair.”

“It’s a really, really great initiative,” says Brant Oldershaw, Director of WSP Canada Inc.’s Southwestern Ontario division. “And it’s really interesting to see the results of these studies.”

ArcelorMittal identifies a type of building – for example, a 12-storey apartment complex – and hires various design firms to design the same building using different materials (mostly steel, concrete, and timber). Those designs are then passed off to a team of consultants, scientists, and contractors, who compare the designs against each other.

By using the same building and the same basic design, but different materials, the science behind Steligence® studies illustrates the difference in performance, cost savings and environmental impact between competing construction materials in a way that simply isn’t possible in the real world.

“We don’t have the opportunity to do apples-to-apples comparisons,” explains Oldershaw. “Every building is different, right? You’re not designing and building three real buildings right next to each other with different materials. So, these studies are really how we can learn about these different applications of these materials.”

When asked for examples, Ransom pointed to the prevalent belief that timber is the “greenest” material to build with. “In some cases, that’s true,” he says. “But, depending on where you’re actually building, steel can come in with a lower carbon footprint, a lower cost.” Even in places where timber still wins, new milling technology and a heavier emphasis on recycled steel means the difference is not as great as normally assumed.

“We get stuck in our rules of thumb,” says Ransom. “But those assumptions aren’t as valuable as they used to be.”

Hitting Green Targets

For Raymond Van Groll, the final panelist and Director, Building Structures at MTE Consultants Inc., this is the true value of Steligence®. “Suddenly, the whole world woke up to Carbon Zero,” he says. “And suddenly, we as architects and designers needed to take the carbon footprint of our projects seriously, because the standards are changing.

“As a design professional, I need the tools so that I’m designing Net Zero.”

Steligence® examines many factors besides carbon footprint, but the impact a building has on the environment is an increasingly large factor for designers. That’s because regulatory bodies are creating increasingly stricter guidelines on carbon emissions – and that has disrupted the construction industry.

“Cost is a factor – it’s always a factor – but now I think we’re also designing more and more to be Net Zero.” Van Groll says, pointing to regulations in cities like Vancouver. “Now, I have real buildings I’m working on where the clients are asking me to show them how we’re hitting those carbon targets. And now, I don’t always have to reinvent the wheel. I can pull up a Steligence® study and say, ‘look, here’s a similar type of building, and these are the findings, so we should do x, y, and z.

“Ultimately, it saves me time and it saves everyone some money.”

“You can start to see trends,” Oldershaw agrees. “You can use reasoning from the studies to deduce what your next building will look like. There will be differences, of course, but you can connect some of the dots.”

While manufacturers are quick to publish studies and papers on their own materials, those studies are presented in a vacuum, all three panelists say. “You can’t really know the actual benefits or values a product will have on a building’s carbon footprint until you put it into context,” Ransom, whose firm mcCallumSather has always emphasized sustainability in their designs, says. “As far as I’m aware, only Steligence® does studies like this.”

Understanding the Whole Building

More than the materials themselves, it’s the application of those materials that Steligence® studies seek to analyze. “One of the biggest challenges we have in design and construction is the misapplication of materials,” explains Ransom. “We can use great products, but we sometimes put them in the wrong place or don’t use them in the right way. Steligence® isn’t about steel. I mean, in some ways it is, but really, it’s about learning the right lessons and how everything fits together.”

“Look at concrete,” Van Groll says, leaning forward. “So, you have the carbon in the material. But, where is the concrete being made? How far does it have to go to get to your site? Those all impact the carbon footprint, right? That’s what Steligence® has been really good at looking at, and why it's really valuable to have.”

That’s not to say that Steligence® is perfect. There are some things that the studies can’t find, and the requirement that each different building have the same practical requirements prevents the architects and engineers from truly optimizing their designs. “Coming up with a design that doesn’t favour one material over another is a real challenge,” says Ransom (before launching into a diatribe against balconies).

And there are clearly ways that the Steligence® program can grow into the future, too. “A lot of the studies have been around residential buildings,” says Oldershaw. “But in the future, I’d love for there to be a Steligence® study on healthcare buildings. Those are usually done in concrete, so I’d be really interested in seeing what the findings there would be.”

“I would love to have one of these studies actually built,” laughs Ransom. “Like, to then have the real world example, to see how well the numbers stack up. But until then, I’m pretty pleased with how these are all done.”

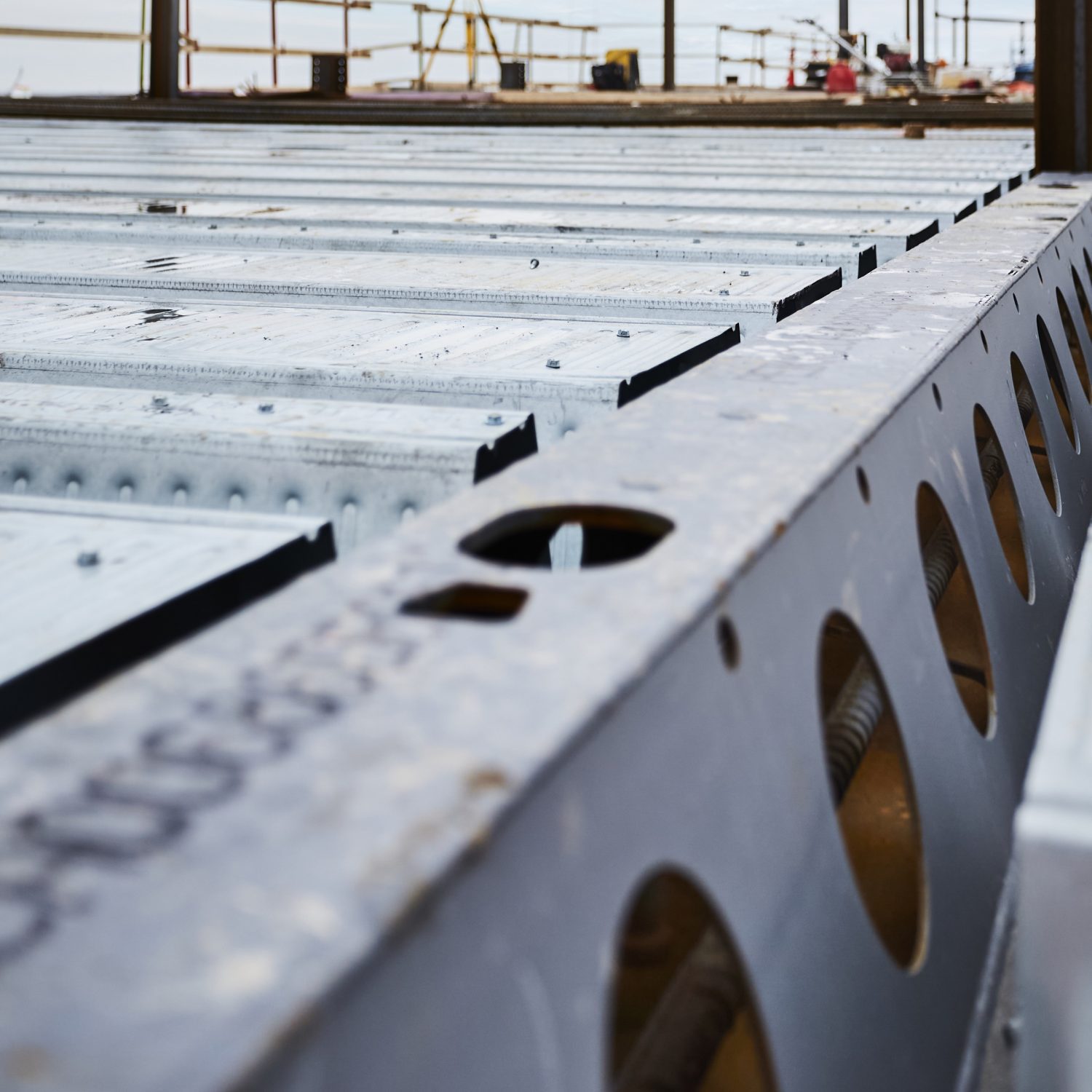

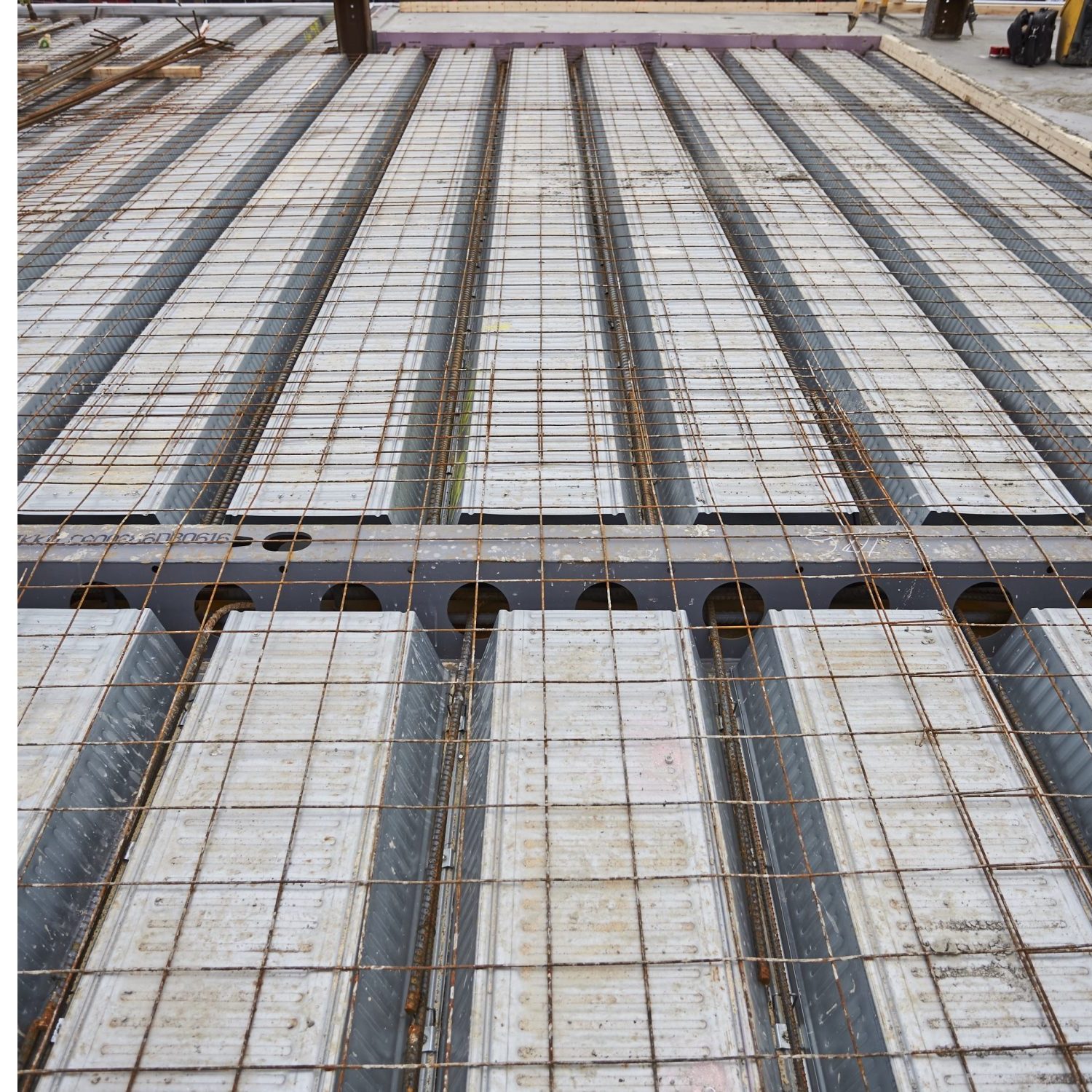

Pictured above: Amica, Oakville, under construction. Constructor Amico, conducted extensive analysis proving it was less expensive to use Comslab / Delta Beams / Light Weight framing, rather than conventional Cast in place concrete.

Specifications

PANEL PARTICIPANTS:

Willems Ransom, B.F.A., M. ARCH., NCARB, AIA | Principal, Architect | mcCallumSather

Brant Oldershaw, M.A.Sc, P.Eng. | Director, Southwestern Ontario | Structural, Mechanical & Electrical Engineering | WSP

Raymond Van Groll, M.Sc (Eng.), P.Eng. | Director, Building Structures | MTE Consultants Inc.

PANEL MODERATOR:

Michael Stiller | Manager, Construction & Manufacturing Products | ArcelorMittal | Global Research and Development

PHOTOGRAPHY:

Photos of Willems Ransom, Michael Stiller, Brant Oldershaw and Amica building by Sandra Mulder

Photo of Raymond Van Groll, provided by MTE Consultants Inc.