Refreshing the Science

The updated results to an old Steligence® study brings opportunity to the forefront

Story: Ian VanDuzer

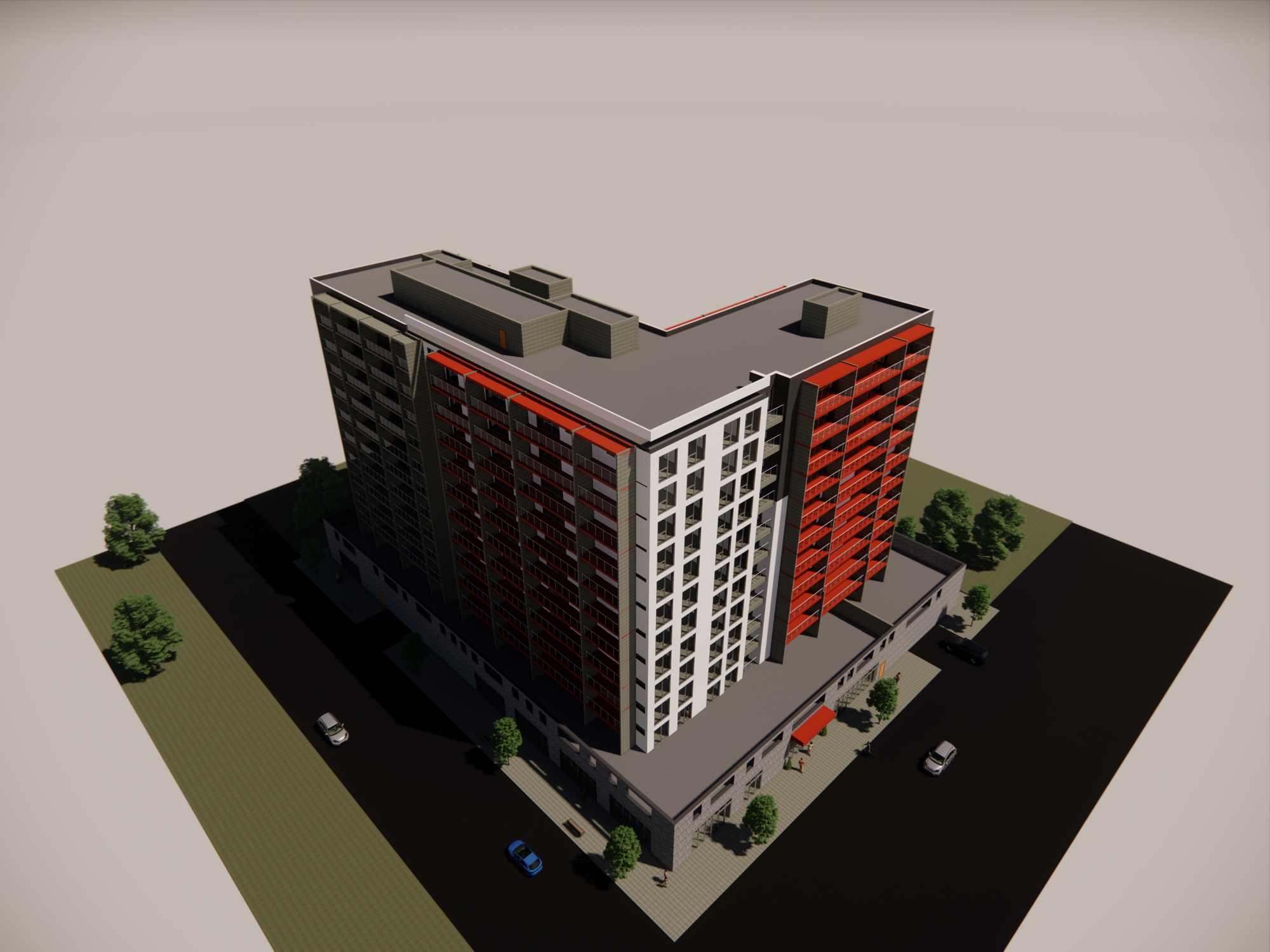

Photography: Renderings provided by McCallumSather

What if you could take something great, and make it even better? Every now and then, you get the rare chance to go back, not to redo, but to rethink. Wouldn’t you want to take another kick at the can, to implement the new information or material, to make your project the best that it could possibly be?

It’s a chance that’s rare in the construction industry, where projects are pretty permanent. That’s what makes the latest Steligence® study—a revision of a previous 2022 paper—so exciting, says Steligence® Projects Manager Matthew Winters. It helps that the study’s 12-storey residential building is theoretical, and won’t actually be built. Even still, Winters and the Steligence® team had plenty of reasons to revisit the study, which found slight advantages in the steel-based designs in terms of embodied carbon content.

“A lot has changed since 2022,” Winters points out. “We have a new Ontario Building Code, which introduced major changes to how we calculate seismic forces for buildings and allows for taller mass timber construction, and we have new products that we thought would deliver interesting results.”

“Together, we saw enough change to justify updating these studies.

Study Overview: What are we looking for?

Steligence® seeks to challenge myths and long-held beliefs across the construction industry, specifically regarding the use of different materials. “There are a lot of established practices, like, if I’m building a high-rise building, and if I want to hit my embodied carbon targets, I need to use this instead of that,” Winters explains. “But those beliefs can be outdated, or they can just be wrong. And we wouldn’t know unless we looked at the science.”

This particular study examines the environmental, cost, and construction time impacts between three functionally equivalent buildings, each predominantly built with a different material: XCarb® recycled and renewably-produced steel, mass timber, and low-embodied carbon concrete. By standardizing design but not materials, Steligence® looks to compare apples to apples, eliminating variables so that clearer conclusions can be drawn.

What’s Changing: Now and Then

Part of the impetus of redoing the study was the emergence of updated, low-carbon building materials, Winters says. “We’re not really changing the fundamentals of the building,” he says, clarifying that the architectural design of the building didn’t change from the previous study. “But in 2022, we didn’t look at mass timber as a material. And we didn’t have XCarb®.”

The emergence of ArcelorMittal Dofasco’s low-carbon steel—whose EPDs were published in 2023—has huge implications on how the material will impact a construction industry that is growing more focused on minimizing embodied carbon to hit government targets. Before Steligence® though, knowing how XCarb® steel stacks up against some of the more-sustainable materials was impossible.

“When the case study was first done, it was just looking at industry-average concrete against industry-average steel,” Winters says. “But now, the industry has evolved beyond looking at industry-average EPDs, and we actually have a steel product that performs much, much better than industry average.”

That brought up another consideration: what to do about the concrete model. “If we’re using an optimized steel solution for environmental performance, it’s not fair if we’re saying, ‘look how much better than concrete this is!’ if we’re using an industry-average concrete,” Winters says.

So, the Steligence® team worked closely with consultants at WSP to find a more optimized concrete mix that would perform on par with the other specialized materials. Another consideration: allowing for longer cure times on anything not on the critical path, which also dropped the carbon content of the model.

Similar considerations were made for mass timber, Winters says. “We focused more on a domestic sourcing strategy, so we’re not unfairly penalizing the product [by moving it across continents].”

“We worked hard to be fair,” Winters says. “And we relied on our consulting partners to ensure we created a level playing field."

The Results (may surprise you)

All of those considerations together delivered some surprising results. “Everything was in the same stratosphere in terms of environmental performance,” says Winters. “Steel came lowest, with timber next, followed by concrete. But there was no massive spread between them, which is a result that surprised not only us, but our whole consulting team.”

How close were the results? Within 5%. “It translates to almost 150,000 kg of CO2e, between the steel and the timber,” says Winters. “But in the grand scheme of something that’s 6.5 million kg CO2e, then it’s actually pretty neck and neck.”

Building cost, too, was strikingly similar. Steel once again performed the best, with the costs of mass timber adding up. Even still, the numbers were reasonably close — a difference of $4 million, on a $90 million dollar construction value.

In the end, the only major discrepancies between the designs was in the construction time. There, mass timber edged out steel, with concrete lagging behind. Steel’s pre-fabricated nature meant that construction time could be slashed at the job site—although not quite enough to overcome the mass timber.

The study—with all its detailed and nitty-gritty results—can be found at Architect’s Corner.

“This is the reality.”

Part of the reason why the results were so similar was because the buildings were designed realistically, Winters says. “There’s a lot of bleed over in terms of materials,” he points out. “Every building has concrete. Each uses steel track and studs. It’s not like we have one building that’s 100% concrete, with no steel. That’s not realistic.”

“It’s less that the building is all steel, and more that it’s the quantity of the steel that made the difference.”

Even still, the parity in the results is surprising. “When I first saw the numbers, I thought, ‘This might raise some eyebrows,’” laughs Winters, “just because I don’t think people expect steel to compete with mass timber in terms of embodied carbon.”

“But we took those results to our project partners, and we dissected the numbers. We worked with engineers and sustainability consultants. We asked, ok, did we miss something? Is there something wrong? Because these results deviate from what the general industry consensus would be. And we ultimately arrived at the conclusion that there wasn’t anything wrong. The results are just what they are.

This is the reality—which is really, really exciting for us!”

An opportunity to learn

If Winters took anything away from the study, he says, it’s that architects and engineers should be more free to explore different materials in their designs.

“There’s no reason why we shouldn’t be seeing greater variation in how our mid to high-rise buildings are being built,” Winters says. “Right now, most mid- to high-rise residential construction going up in the Greater Toronto Area is concrete, but we’re proving that there are three viable material options.”

And, from a steel perspective, it was good to see the numbers surrounding XCarb®. “That’s where some satisfaction came in,” Winters grins. “Where we can say now, ‘Hey, we’ve got a pretty great product here, and we have the results to back it up.”

SPECIFICATIONS

12-Storey High-Rise Residential Building Case Study:

WSP, MTE, and RJC Engineers were the external structural engineering consulting partners that contributed to this case study. McCallumSather Architects was the external architectural partner. Mantle Developments provided third-party review of the life-cycle assessment, and Hanscomb provided construction scheduling and cost estimates.