Growing Green

Clearly, why growing up – not out – is the answer

Story: Julia Preston, Ian VanDuzer

Photography: (Renderings) mcCallumSather

Which would you rather have: 55 city blocks, or an orchard that can grow 22 million apples?

They both take up the same amount of space (121 hectares / 300 acres), but one increases urban sprawl, encourages more cars, and increases pollution, while the other grows food while also sucking CO2 out of the atmosphere.

It’s an easy answer, right?

That’s what more and more cities are finding as they look for solutions to expanding urban sprawl. People will always gravitate towards cities for the opportunities they provide, and they will need to find places to live as well as work. The challenge becomes how to manage growth in a sustainable manner. For most urban centres, that means growing up – into the sky – instead of sprawling out.

High-rise skyscrapers have become a go-to housing option in most cities, but they’re changing as fast as the places where they’re built. Concrete has long been the dominant construction material for tall buildings, but recent advances in cold formed steel grades and innovative member design mean that sheet steel can be used as an alternative in many aspects of building construction.

“There’s been a big push from a lot of the manufacturing companies in the last 20 years where... the product is becoming more complex because you’re solving greater problems and they’re providing solutions,” explains Greg Parlardg, product manager at Bailey Metal Products. “Steel was always there

but now the design community and the manufacturers are embracing that type of building material and creating new products that can achieve greater values than before.”

A tale of two buildings

What does steel do that concrete can’t?

A new Steligence® study from ArcelorMittal Dofasco aimed to find out. Steligence brings together teams of independent industry experts along with the latest building information modelling technologies to analyse the impact of different construction methods.

The study compared two design scenarios for a 12-storey residential high-rise constructed in the Greater Toronto and Hamilton Area: concrete and steel.

Each high-rise was 26,655 square metres and had 209 residential units of one- and two-bedrooms spread over 11 floors. The ground floor housed the main entrance, amenities, services, utilities, and access to underground parking in the basement level.

The only differences between the two buildings were the structural elements and materials they used.

Both designs used cast-in-place (CIP) concrete columns and slabs for the basement and lower floors, light steel framing for interior walls, and insulated steel stud walls with metal panels on the exterior.

Steligence® allows building owners, architects, and engineers a fact based approach to view building construction, for collaboration to build sustainable, more cost-effective buildings.

| Steel | Concrete | |

| Foundation & Underground Parking | Cast-in-place (CIP) concrete columns, slabs | Cast-in-place (CIP) concrete columns, slabs |

| Lower Floors (1 & 2) | CIP concrete columns, slabs | CIP concrete columns, slabs |

| Upper Floors & Balconies | COMSLAB®, Precast concrete balconies | CIP concrete floors slabs & balconies |

| Structural System | Light steel framing walls, HSS columns, W-beams | CIP concrete columns & beams |

| Interior Walls | Light steel framing | Light steel framing |

| Core, Shear Walls | COMWALL™ | CIP concrete |

| Exterior | Insulated steel stud wall, metal panel, window wall glazing | Insulated steel stud wall, metal panel, window wall glazing |

| Roof | COMSLAB® | CIP concrete slabs |

But things changed at the second floor. The steel building used composite decking versus the same CIP columns of the concrete building. Dan Van Gageldonk, technical sales representative with Bailey, explains that with composite decking “you’re using about 50 per cent less concrete and 70 per cent less rebar specifically for the floors.”

Less materials, Van Gageldonk explains, means less transportation, less cost, and less impact on the environment.

The structural system on the steel high-rise used light steel framing walls, hollow structural section (HSS) columns and W-beams, again eliminating the need for CIP concrete. Core and shear walls used Bailey’s prefabricated composite wall, trade named COMWALL™.

COMWALL™ is a stay-in-place forming system that uses light-gauge steel framing members to build concrete walls for shear and core walls. It can also be installed by the steel framing contractor, which increases efficiency in the construction process.

“If we utilize steel throughout the whole building, you reduce the need for certain trades,” says Van Gageldonk. “The people who are installing the walls and the floors can often install your cores. If you don’t… you would need a crew to come in and cast in place just those walls. Steel allows for seamless integration.”

Going green at no added cost

The Steligence study assessed construction time for both designs and found the schedule was similar, with concrete taking 412 days and steel taking 415. They cost almost exactly the same, too: the concrete building cost $56.1 million, and the steel version totalled $55.9 million.

The real difference emerged when the buildings were assessed for their environmental impact.

The Steligence team used the Tally® plug-in for Autodesk Revit to compare the two design scenarios from cradle-to-grave for the 60-year lifespan of each structure.

Less materials = Less transportation, less cost and less environmental impact.

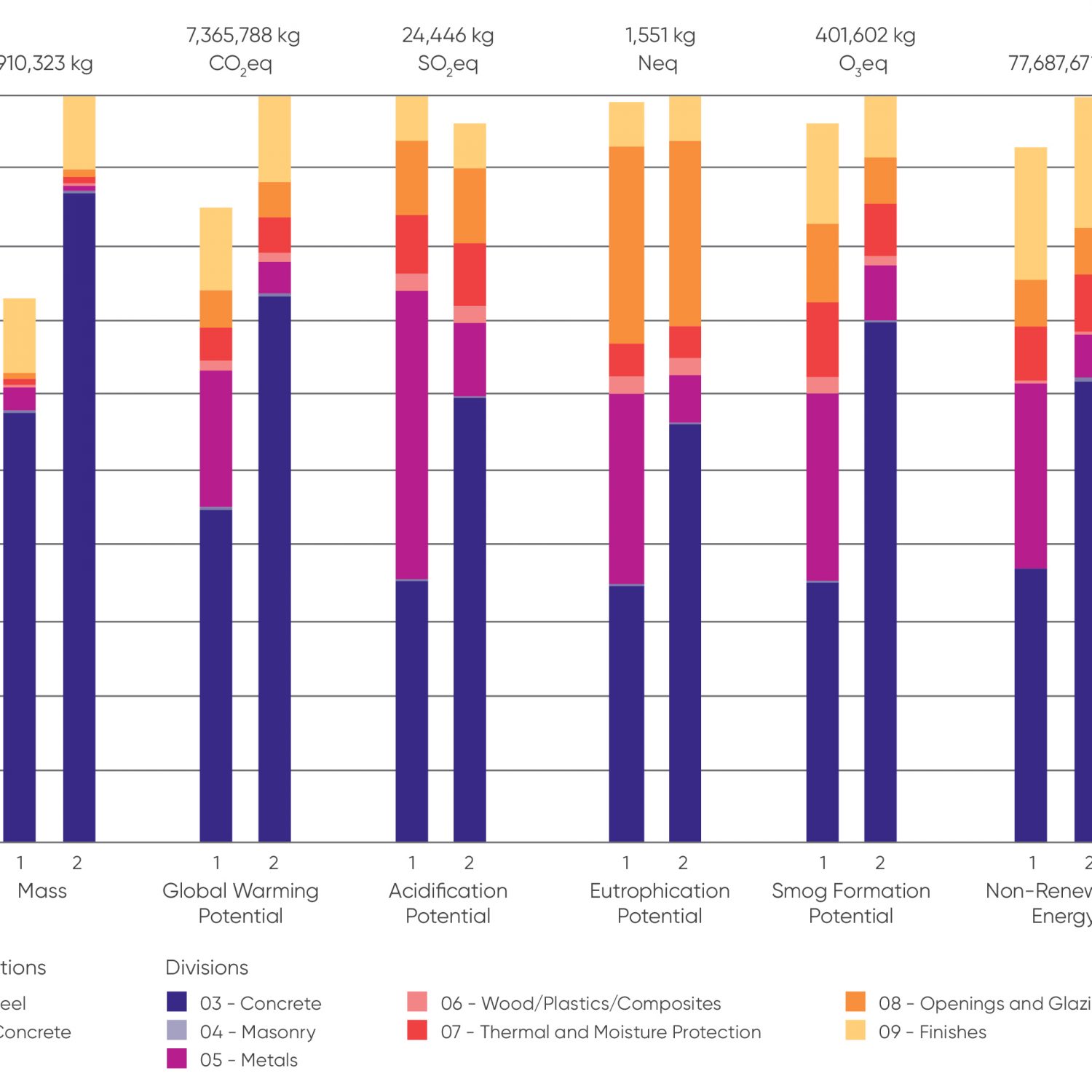

The assessment used the bill of materials and North American environmental product declarations (EPDs) from GaBi life cycle inventory and looked at global warming, acidification, eutrophication, smog formation, and non-renewable energy.

Results showed both designs were comparable across four of the five impact indicators, but the steel-based design showed a significant advantage in global warming potential. Steel saved approximately 1.1 million kg of CO2 eq when compared to the concrete design.

This is equivalent to a single building taking 220 cars off the road.

The decrease was primarily due to the 27 per cent weight savings in the steel-based design. Concrete in both designs was the largest material contributor across the five environmental

impact indicators.

Parlardg sees steel as a clear choice to advance more sustainable building practices. Steel used in construction today is fabricated from overwhelmingly recycled content, even as manufacturing methods are becoming more efficient and greener.

“You can build a building with steel. Twenty years later you can remodel that building, either reuse that product because there will be no degradation in its performance, or you can put that into your blue bin... and it can get melted down and turned into steel studs again for another project. There’s no other building material that has that type of story that I know of,” Parlardg explains excitedly.

The findings are as clear as glass

However, both Parlardg and Van Gageldonk admit that sustainability is only one page of the story.

“The green story is very nice, but it can’t cost anyone more. And it can’t reduce performance in any way,” admits Parlardg.

Telling the full story of steel high-rise construction is one of the goals of the Steligence study. By analysing building designs from multiple factors, the study shows that steel is an alternative that doesn’t forgo quality, cost, or schedule.

While there was limited financial advantage between the two designs, the sustainability of steel construction was clear with a 15 per cent reduction in Global Warming Potential.

Steel construction had GWP reduction of 15%.

This result is consistent with other Steligence case studies, which have shown steel’s superior environmental performance not only in high-rise buildings, but also in office, mid-rise, and Passive House builds.

The findings are clear: steel should be the top design choice as the building industry aims to reduce its carbon footprint.

Case Study Team

DESIGN:

mcCallumSather // mccallumsather.com

STRUCTURAL ENGINEERING:

WSP (concrete) // wsp.com

Atkins + Van Groll (steel) // atkinsvangroll.com

Bailey Metal Products (steel) // bmp-group.com

ENERGY MODELLING:

mcCallumSather // mccallumsather.com

MECHANICAL ENGINEERING:

mcCallumSather // mccallumsather.com

ELECTRICAL ENGINEERING:

Seguin Engineering // sei-ee.com

COST CONSULTING:

Altus Group // altusgroup.com

SCHEDULE CONSULTING:

MPa Consulting