Cool Kids on the Block

Norbec expansion highlights importance of steel in new construction.

Story: Ian VanDuzer

Developers today seem to be caught more and more in between a rock and a hard place. It’s no longer enough to build buildings – whether residential towers, manufacturing plants, or everything in between – that are safe, durable, and suited to their tenants’ needs. They now have a whole suite of other considerations to contend with:

“How much will heating and cooling cost in this age of rising temperatures? How sustainable are our materials? What will our carbon footprint be during construction and for the lifecycle of the building?”

It’s a tricky situation, to be sure, but one that Norbec President Jan Lembregts seems to think has a simple solution: insulated steel. Steel is not new to the world of construction, but new applications, treatments, and finishes are being experimented with every day. Steel can do more than ever before: no longer constrained to serving as building supports, steel serves as building exteriors, envelopes, and – yes – insulation.

Cold Steel

Norbec’s primary products all revolve around Insulated Metal Panels – or IMPs. These are used in all sorts of products: from prefabricated cold rooms and refrigerators, to exterior steel panels, to specialized usages such as greenhouses and food processing applications.

But how does it work? Steel is traditionally a conductor, not an insulator, but Norbec – and other manufacturers like them – have found ways to shore up this characteristic of steel and turn it into a strength.

Norbec IMPs are made by squeezing insulating materials – like Rock Wool or polyurethane – between two steel sheets. This effectively insulates the sheets while also protecting the insulation from other elements. Standard construction requirements like vapour barriers and thermal breaks are rendered unnecessary due to the steel wrapping. And the panels are generally flame resistant, too – the steel protects the interior insulating materials from any fire.

The seal is so strong that IMPs can be used in environments usually covered in water, like pools and the aforementioned refrigerator rooms, without fearing that the water will impact the insulation. Integrating the insulation into the panels makes them remarkably energy-efficient, saving money on heating and cooling while also reducing carbon footprints.

Then there are the construction benefits: IMPs can be quickly installed and – because they are already insulated – cut down on construction stages. Traditional construction systems can take up to 11 steps, but with IMPs, there’s only one. In fact, Norbec says that using their IMPs instead of other multi-stage assembly systems can cut construction times down by 50%. That represents a lot of time and, just as importantly, a lot of money.

A New Plant

With all of these benefits, it’s easy to see why demand for IMPs is growing. “We have seen probably high single digit growth in insulated metal panels year over year,” Lembregts says, before noting that the growth is region-dependent. “Quebec and Ontario have a faster adoption rate of insulated metal panels compared to some of the U.S. markets.”

But, Lembregts says, the prevalence of IMPs are starting to spread south of the 49 th parallel. “You see some growth in the Midwest, in New England and the Northeast. IMPs are being adopted fairly rapidly with the building codes and energy requirements changing.”

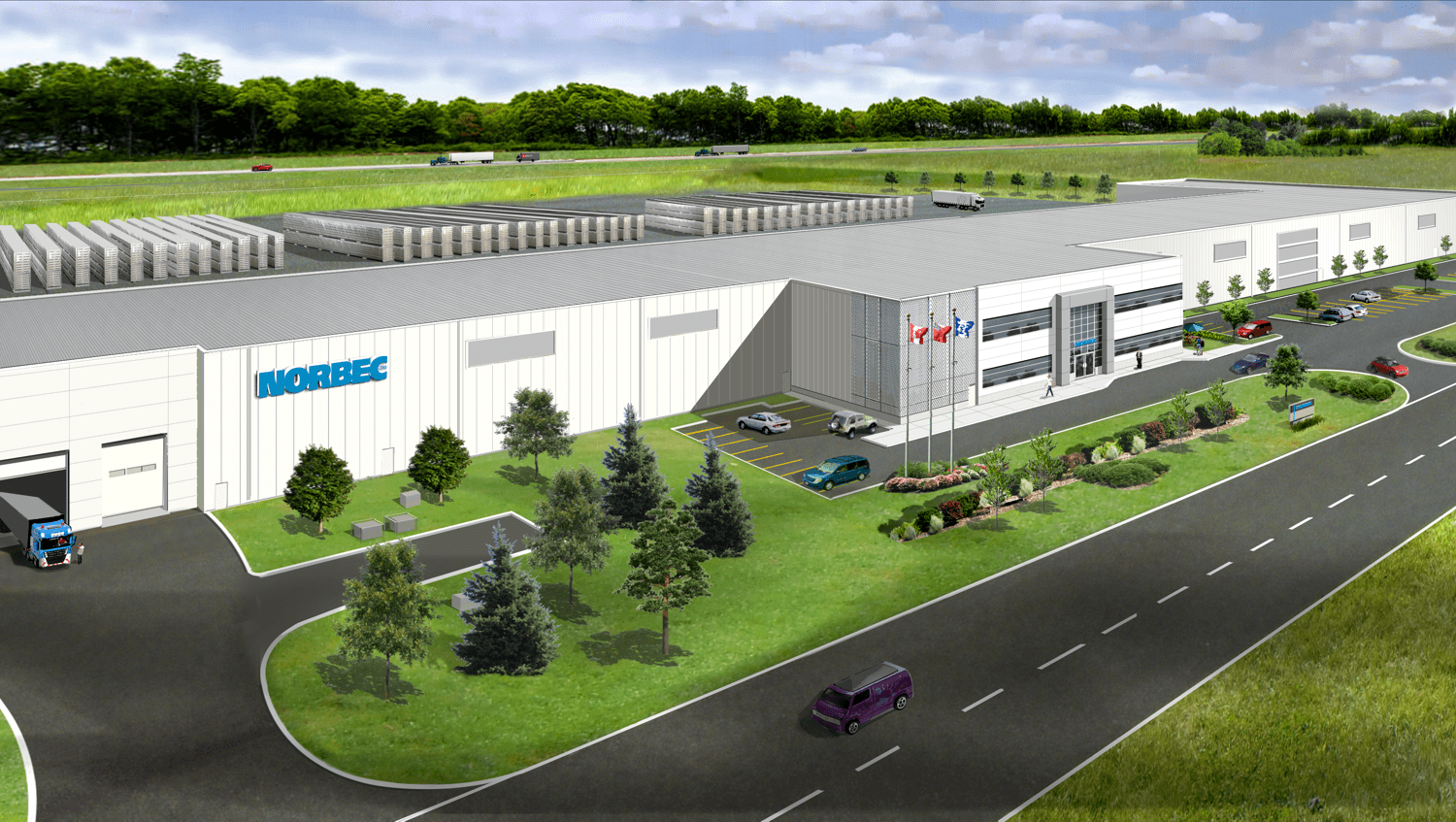

With demand clearly on the rise, Norbec knew that they had to expand to meet future demand. In May, Norbec announced the construction of a new manufacturing plant in Strathroy, Ontario, between the city of London and the border crossing in Sarnia.

“It’s a big investment for us!” Lembregts excitedly says. “It’s a big step for us and one that we feel ready for and excited to have.”

When asked, Lembregts was clear why Strathroy was the ideal spot. “It’s a matter of proximity to the market,” he explains. “Delivery is an important component of the total cost of the panels. We like southwestern Ontario because it gives us good access to the GTA and the entire Ontario market, and the proximity to the U.S. Midwest.”

And also, Lembregts notes, proximity to the source of the steel. Strathroy is about 40km west of London, Ontario, putting it in a prime location in terms of access to transportation infrastructure. A dominant share of Norbec’s steel purchases come from the ArcelorMittal Dofasco steel mills in Hamilton, Ontario, mere hours from the new plant. “We don’t think it’s a viable model to import steel, repaint steel from overseas,” Lembregts explains.

New, Hip, Cool.

The new facility has been described as “ultramodern” by Norbec. “It will be very automated,” Lembregts says.

“Already, our existing factory processes are automated. But this plant will be even more automated than what we had before.”

That automation has an impact on the employees, as well. Lembregts estimates that 70 permanent jobs will be created to fully operate the plant. Those are 70 high-skilled, desirable jobs that are being added to a small, local economy.

So, not only are IMPs efficient, sustainable, and practical, but they look good, too!

Lembregts is clear that the focus of the Strathroy plant will be the production of specialized products. “Steel for the architectural market is a premium product,” he says. The Strathroy plant will be able to produce steel with a variety of finishes, textures, and colours – including wood accents.

“We standardize as much as possible,” Lembregts explains. “But in the architectural space, many things can be customized the right way to make it unique. It’s a value for architects that we can incorporate their designs and their specifications.”

So, not only are IMPs efficient, sustainable, and practical, but they look good, too!

Cool Runnings

More than anything, a $45 million investment into a new production facility signals more than the growth of one single company. It’s a sign that insulated metal panels are in high demand, and will serve as a significant and prevalent building material in this new age of construction.

When you start to see more and more exterior steel on buildings – more and more sleek panels and sharp, crisp, distinct lines – you’ll now know why and you’ll have a good idea where this steel is coming from.

Specifications

PROJECT OWNER:

Norbec // norbec.com

PRESIDENT:

Jan Lembregts

PLANT LOCATION:

Strathroy, Ontario, Canada