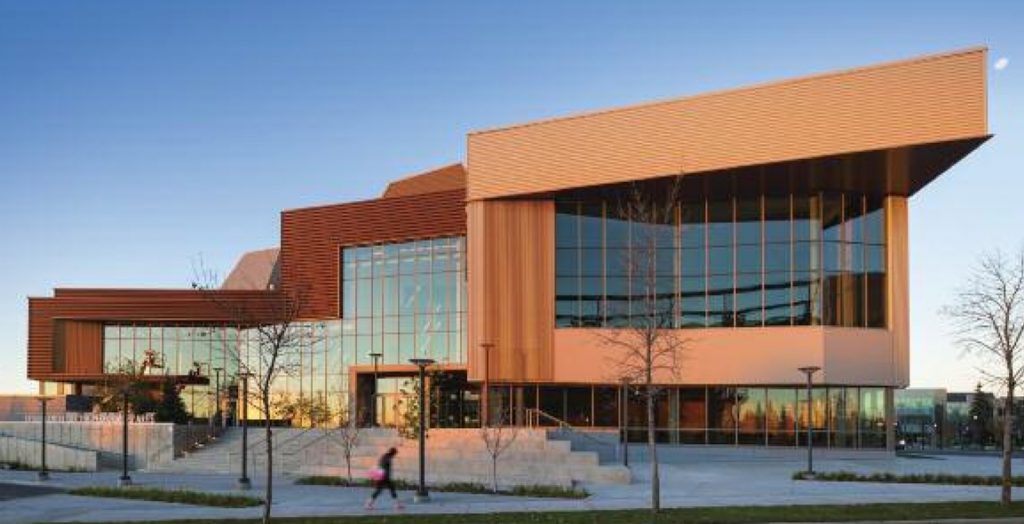

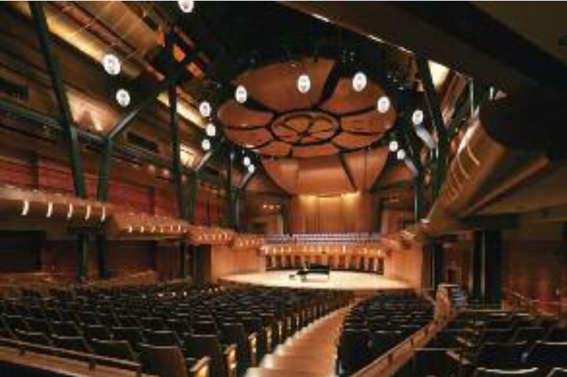

The Taylor Performing Arts Centre is music to students’ ears at Mount Royal University in Calgary. Designed by Pfeiffer Architecture, construction on the new addition to the school was begun in 2011 and finished in the Fall of 2015. The Centre’s crowning glory is the 800-seat Bella Concert Hall, which features a stunning Alberta rose looking over the stage.

The Conservatory features the 800-seat state-of-the-

art Concert Hall as the centerpiece. Percussion rooms, public rooms and music classrooms surround the concert hall. Six rehearsal halls, 51 studios, additional classrooms, administration areas, lobby, a back-of-house operations area and a designated wing for the Conservatory’s Early Childhood music programs.

The obvious benefits of pre-painted cladding are time and money. “Pre-painted cladding also allowed the metal seam work to be better defined, which is what we wanted”. Quality control is also improved, since the paint is approved before it goes to the site.

The Mount Royal University Conservatory and Concert Hall has been designed and constructed to satisfy the energy and environmental requirements of the LEED® Canada for New Construction and Major Renovation 2009 Green Building Rating System. The construction materials were diverted from the landfill whenever possible and achieved a 80% diversion rate.

“We took the whole idea of the prairies as well as the history of the prairies and communicated it through the language of architecture,” says Bill Murray, Principal Architect. “The building was inspired by the geography and geology of the area. It is meant to look like a hierarchy of parts, like you’d see when you’re driving through the mountains, with the concert hall as its peak.”

Murray adds that incorporating history into the design was crucial, as Mount Royal University’s one-hundred-year old music conservatory is the oldest of its kind in Canada. “It’s about being part of something historic that’s expressed in a contemporary way,” he says. “People love this space when they walk into it. It is very rich.”

“The orchestra canopy, an interesting design element, throws the sound back to the orchestra but it also moves the sound around the room,” says Murray. “The acoustics are supreme.” Since the structure’s walls are concrete, a significant amount of steel was required to support their weight. Murray describes what he calls a “barn-like” structure of steel inside the concert hall. “A lot of steel was used in both the structure and cladding of this building.

The entire building frame is structural steel and the wall cladding is roll-formed pre-painted steel. Steel was chosen for economic reasons and for its relatively light weight,” he says. “The shapes we were going after were much easier to achieve with steel, which is what we wanted.”

Lead architect Bill Murray, devised a design incorporating the structural elements that reflect the rural prairie heritage of Alberta. The massing of the building draws associations to the tectonic forces that created the Rocky Mountains, above the lower forms – metaphorically alludes to the singular barn in the landscape.

This 9,290 m2 (100,000 sq. ft.) project, completed in the summer of 2015, was designed to achieve future LEED® Gold certification and serves as the beating heart of the Mount Royal University campus. The Conservatory features the 800-seat state-of-the-art Concert Hall as the center piece, six rehearsal halls, 51 studios, additional classrooms, administration areas, lobby, back-of-house operations area as well as a dedicated wing for the Conservatory’s Early Childhood music programs.

The Taylor Performing Arts Centre is connected to the Centre for Continuous Learning. It was constructed with funding from the federal, provincial and city governments, with the rest of the monies raised from the Taylor family and other private donors.

The Conservatory and Concert Hall has been designed and constructed to satisfy the energy and environmental requirements of the LEED Canada for New Construction and Major Renovation 2009 Green Building Rating System.

WALL CLADDING:

PRE-PAINTED STEEL THICKNESS:

0.76mm (.0299”)

COATING WEIGHT:

Z275 (G90) galvanized

PAINTSYSTEM:

Kynar/WeatherXL

CLADDING PROFILES:

AD300, CL3100, 7/8 CORRUGATED, CL7040

COLOURS:

Classic Copper QC9559; Grey Silt QC09653; Aged Metal QC8591B; Charcoal QC6072

DESIGN AND CONSTRUCTION TEAM

OWNER/DEVELOPER:

Mount Royal University

ARCHITECT:

Pfeiffer Partners Architects 213-624-2775 and Suhari + Partners Architecture Inc. 403-228-9307

STRUCTURAL ENGINEER:

Reed Jones Christoffersen Ltd. 403-283-5073

CIVIL ENGINEER:

Jubilee Engineering Consultants Ltd. 403-276-1001

MEP:

H. H. Angus & Associates 416-443-8200

CONSTRUCTION MANAGER:

CANA Construction 403-255-5521

THEATRE:

Auerbach Pollock Friedlander 415-329-7528 and 212-764-5653

ACOUSTICS:

Talaske 708-524-2800

AUDIO/VISUAL:

Multi-Media Consulting, Inc. 650-578-8591

STRUCTURAL STEEL SUPPLIER:

Glenmore Fabricators 403-203-4976

STEEL CLADDING SUPPLIER:

Vicwest 780-454-4477

STEEL CLADDING INSTALLER:

Skyline Roofing Systems 403-277-0700

LIGHTING:

Francis Krahe & Associates 213-617-0477

LANDSCAPE ARCHITECT:

818 Studio Ltd. 403-244-8188

PHOTOGRAPHY:

CANA Construction, Ema Peter Photography 604-789-6339