Innovative design utilizing pre-painted Galvalume Cladding and Hollow Structural Steel framing

This centre is a state-of-the-art, multi-discipline performing arts space designed for community and professional use. Since its opening it has housed dance, theatre and musical performances of all types and skill levels.

It is on the campus of Menlo-Atherton High School, surrounded by the semi-rustic environment of Menlo Park. The project’s highly conceptual design was inspired by the surrounding heritage valley and coastal oak groves on campus.

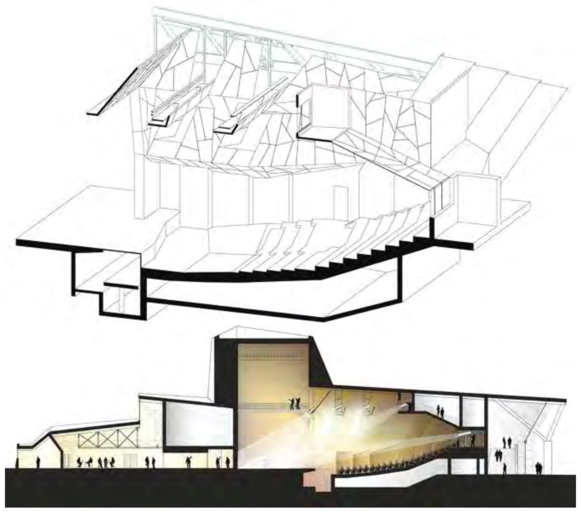

The interior of the centre is dominated by a five-hundred seat auditorium which can be optimized acoustically for either dramatic performances or musical events. It includes a 19.8m (65-foot) high loft, fly gallery, stage house, orchestral lift, practice and academic meeting spaces, a “green” room and a cafeteria/warming kitchen.

“At the heart of Hodgetts + Fung’s vivid, tactile architecture is an ability to heighten the way people see

and experience space.”- Alan Hess

With the objective to bring music and drama to its students and the surrounding community, this 2,880m2 (31,000 sq. ft.) performing arts building is located on the campus of Menlo-Atherton High School, an arts-oriented high school. It features broad, over-hanging eaves – designed to complement existing low-slung classroom buildings and monumental structural trees – which echo the entry grove of historic oaks.

Photograph showing hollow structural steel (HSS) used for the light support framing in lobby area.

Steel struts surmounting massive concrete columns complement the oaks facing the lobby and support the exposed structure of the roof above the depressed entry courtyard sheltered by a branching structure designed to inspire spontaneous outdoor performances. Broad overhanging eaves designed to complement the surrounding low-slung classroom buildings and monumental structural “trees” which echo the entry grove of historic oaks.

The building is configured to serve both a formal, regional audience and a more casual group of parents and students. A direct response to the community’s revered heritage oak trees established the axial alignment and served as the governing metaphor for the building’s structural, volumetric and aesthetic development.

The interior of the centre is dominated by a five-hundred seat auditorium which can be optimized acoustically for either dramatic performances or musical events.

SUSTAINABILITY OBJECTIVES

An energy saving H-Vac system, which distinguishes between the rarely occupied auditorium and the heavily used support facilities – scenic shop, rehearsal room, and community space – is programmed to harvest cool or warm air and direct it to the occupied portions of the facility. Operable windows allow for heating and cooling, while occupancy sensors keep lighting needs regulated indoors and out.

An under floor plenum delivers conditioned air directly to seated theater patrons by means of registers under each seat. This technique avoids the waste associated with conventional systems by providing tempered air at the occupied zone. Sustainable, yet visually rich materials such as exposed steel – have been carefully detailed with laser cut precision to form the public spaces in the lobby and theatre

Variations in the relationship of the folded planes of the roof to the surrounding landscape provide opportunities for student meeting places and mechanical equipment. To the south, steel struts surmounting massive concrete columns complement the oaks facing the lobby, and support the exposed structure of the roof above the depressed entry courtyard sheltered by a branching structure designed to inspire spontaneous outdoor performances.

PROJECT SIZE:

2,900m2 (31,209 sq. ft.)

ROOF DECK:

.91mm (.036”) G60 Galvanized ASTM A635 Grade 33.

ROOF CLADDING:

.61mm (.0239”) AZ50 Galvalume (AZM150 in Canada) 22.2mm rib x 457mm

(7/8” rib x 18”) wide flat panel, standing seam roof, coloured Champagne in the Kynar paint system.

HSS SECTIONS AT PATIO:

HSS Diagonal Braces: HSS 304.8mm x 304.8mm x 15.87mm (12” x 12” x 5/8”) A500 Grade B (Diagonal bracing at patio).

HSS Pedestal Base: HSS 457mm x 12.7mm (18” x 1/2”) A500 Grade B.

HSS SECTIONS – LOBBY:

HSS Light Support Framing – Roof framing above: 355.6mm x 558.8mm (14” x 22”) beams Grade A992.

HSS hangers from WF beams above:

HSS 152.4mm x 101.6mm x 12.7mm (6” x 4” x 1/2”) A500 Grade B.

HSS horizontal members:

HSS 152.4mm x 101.6mm x 6.35mm (6” x 4” x 1/4”) A500 Grade B.

HSS skewed light support beams:

HSS 152.4mm x 101.6mm x 6.35mm (6” x 4” x 1/4”) A500 Grade B.

Diagonal angle bracing: 50.8mm x 50.8mm x 7.94mm ( 2” x 2” x 5/16”) A36.

Roof Framing above: W12 and W16 beams Grade A992.

GUARDRAIL FRAME – ALONG MAIN STAIR ASCENDING TO 2nd FLOOR

Top, intermediate & bottom rails: HSS 101.6mm x 50.8mm x 3.175mm (4” x 2” x 1/8”) A500 grade B.

Stub pieces between rails: HSS 152.4mm x 50.8mm (6” x 2”).

Steel Deck above brace assembly/roof framing: .91mm (.036”). G60 Galv.

Grab rail: 38.1mm (1-1/2”) standard pipe.

Grab rail brackets: 38.1mm (1-1/2”) thick shaped/bent plate A36.

Pictured above: HSS 304.8mm x 304.8mm x 15.875mm (12” x 12” x 5/8”).

Roof support w/plate assembly (penetrating glass): A500 Grade B 609mm x 1,397mm (24” x 55”) and assorted size WF roof beams Grade A992.

DESIGN AND CONSTRUCTION TEAM CLIENT:

Sequoia Union School Board

ARCHITECT:

Hodgetts + Fung Design and Architecture 323-937-2150

GENERAL CONTRACTOR:

Blach Construction Co. 408-244-7100

STRUCTURAL ENGINEER:

Englekirk Structural Engineers 323-733-6673 or 714-557-8551

MECHANICAL ENGINEER:

IBE Consulting Engineers Inc. 818-377-8220

CIVIL ENGINEER:

BKF Engineers Surveyors Planners 650-482-6300

ACOUSTICAL:

Akustiks 203-299-1904

THEATRE:

Fisher Dachs Associates 212-691-3020

LANDSCAPE:

Tanaka Design Group 415-863-7800

FABRICATOR/ERECTOR:

Concord Iron Works, Inc. 925-432-0136

STEEL DECK SUPPLIER:

Verco Decking Inc. 916-488-8180

STEEL DECK INSTALLER:

B.T. Mancini Co. Inc. 408-942-7900

PHOTOGRAPHS:

Courtesy Hodgetts + Fung Design and Architecture