Steel plays a significant role in the Renewal and New Construction of Terrace Sportsplex and Vanderhoof Aquatic Centre

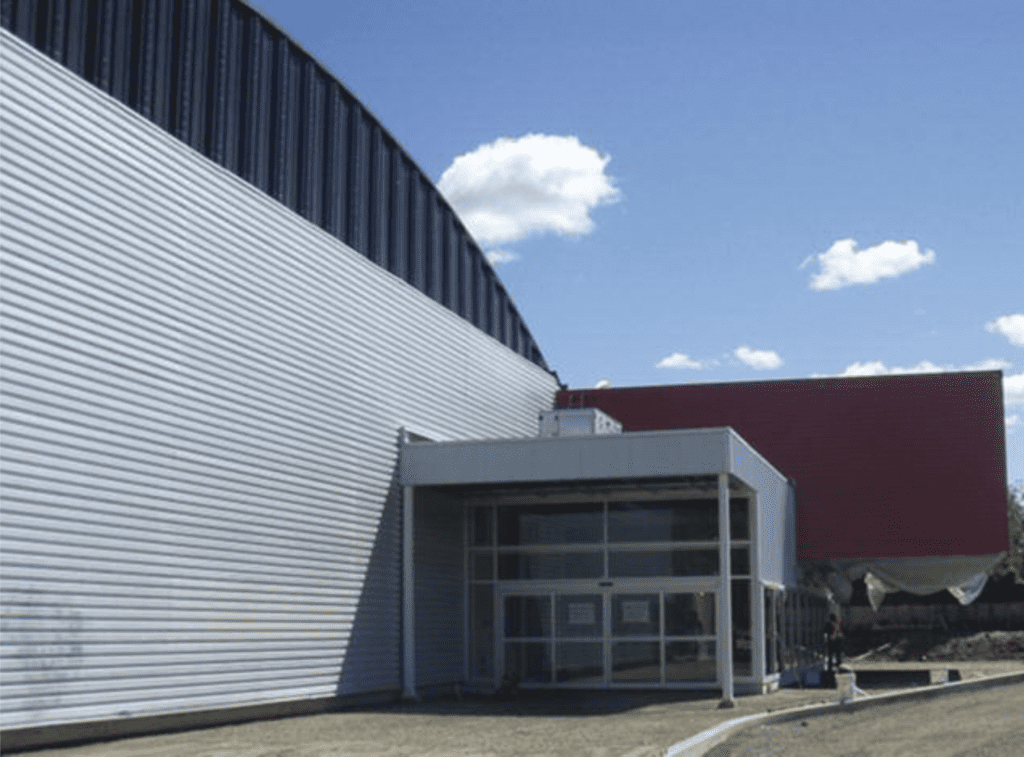

Steel design has played a vital role in structures intended to revitalize their communities. The architects designed practical solutions to twinning the existing arena as the first step in the Terrace Sportsplex Project Revitalization. A pre-engineered steel building by Behlen Industries was used for the second arena, which provides an important training ice surface for hockey-crazy Terrace.

Through careful budget planning, interior improvements were made to the existing arena and Sportsplex. These improvements focused on improving spatial flow, both in the first and second floor entrance ways and in some exterior improvements, including replacing wood cladding. The project is strongly characterized by a cantilevered multipurpose space, designed to take advantage of Terrace’s impressive mountain views. The second floor addition provides a canopy over the entrance, much needed community-use space, as well as warm, second floor viewing areas for both ice sheets.

Subsequently, Carscadden Stokes McDonald worked with the City of Terrace to complete a full review and assessment of the Aquatic Centre located in the same campus of facilities as the Sportsplex. In regard to the Vanderhoof Aquatic Centre, a whole new facility was built, replacing the old aquatic facility.

"Pre-painted steel is an elegant material to work with. It is durable, low maintenance, colourfast and it comes in a number of profiles we like, plus it’s a delight to work with.” said Ian McDonald, partner architect.

Armen Mamourian, principal architect with Carscadden Stokes McDonald Architects Inc., explains the revitalization at the Sportsplex, “the community of Terrace had hoped to twin their existing ice sheet at the Sportsplex to meet growing demand”. Armen continues, “earlier attempts were coming in over budget, so this new design exploited steel structures in general and stressed skin-steel buildings in particular, to meet the demands for long spans, durable surfaces, and simple foundations,” he says.

A Convex frameless steel building system, by Behlen Industries was used in the Terrace Sportsplex Revitalization for the second ice surface. This steel building system (SBS) approach was chosen for its ease of constructability, spread footings and serviceable interiors. Additionally, the frameless approach provided clean and clear interiors with natural ceilings. The stressed-skin steel building addition mimicked the form of the existing roof, while providing a practical, modern solution. The exterior cladding of the second arena is clad with AZM180 Galvalume coated steel.

Meanwhile, in Vanderhoof, building a local aquatic facility had been a community aspiration for years. The district undertook extensive public consultation and a successful referendum to determine the type of facility which would add value to the local area as well as gaining access to the funds required to bring the project to reality.

The project is strongly characterized by a cantilevered multipurpose space, designed to take advantage of Terrace’s impressive mountain views.

Above: Unpainted .61mm (.0239”) AZM180 Galvalume in the Ultra Span profile along with 1.22mm (.048”) AZM180 Galvalume, coloured Black in the CS75 profile, can be seen on the end of the Frameless Convex steel building system of the 2nd Terrace Arena.

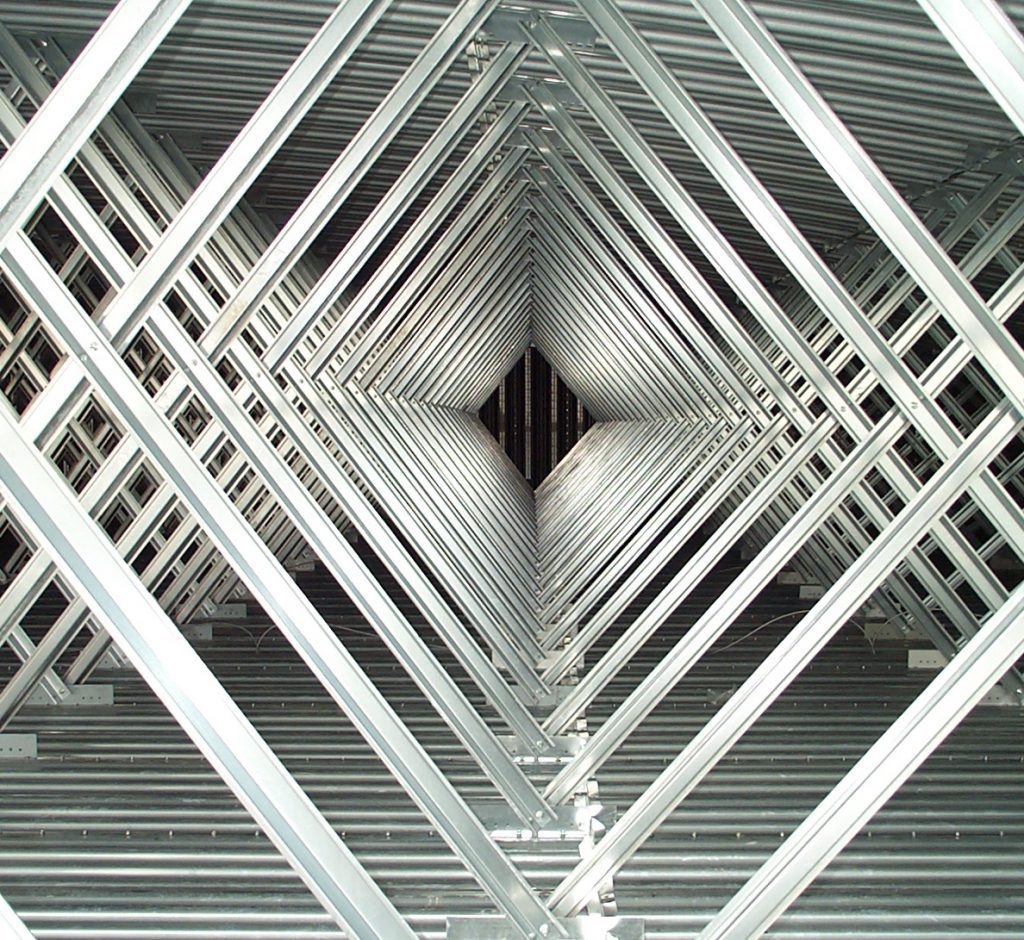

Above: Attic trusses can be designed for varying loads by changing the gauge. This allows the roof system to accommodate heavy loading capacity.

"Again, while there was a strong desire to showcase wood elements, as the forestry industry is a big local presence, the budgetary considerations and large spaces unimpeded by structural elements led us to an elegant steel framed build- ing solution,” says Mamourian. “The construction of the new aquatic facility is intended to promote public health and year-round activity for the town’s residents. It is located next to the existing ice arena in the centre of town to create a convenient and accessible athletics precinct.” While a pre- engineered steel building was used for the Terrace Sportsplex revitalization, steel framing and steel roof deck along with steel roof cladding was used for the Vanderhoof Aquatic Centre. Wood has been used in the building’s interi- or finishes in a nod to the local forestry industry.

The structural steel roof of the Vanderhoof Aquatic Centre is a striking focal point, McDonald says. “I think it’s quite shapely. The design was meant to evoke the landform of the surrounding topography. The crinkled and folded roof is pretty dramatic.”

The Sportsplex revitalization was completed in December 2018 and the Vanderhoof Aquatic Centre in January 2019.

Below: Budgetary considerations and large spaces, unimpeded by structural elements, led us to an elegant steel framed building solution for the Vanderhoof Aquatic Centre,” says Mamourian. The photo below shows the extensive use of wide flange beams, hollow structural sections (HSS), steel roof deck and structural steel pipe.

DESIGN AND CONSTRUCTION TEAM - TERRACE SPORTSPLEX REVITALIZATION:

ARCHITECT

Carscadden Stokes McDonald Architects Inc. 604-633-1830

STRUCTURAL ENGINEERS

CWMM Consulting Engineers Ltd. 604-731-6584

GENERAL CONTRACTOR

Viking Construction Ltd. 250-562-5424

STEEL WALL CLADDING SUPPLIER – FITNESS ROOM ADDITION

Vicwest 800-387-7135

STEEL CLADDING INSTALLER – FITNESS ROOM ADDITION

101 Industries Ltd. 1-877-632-6859

STEEL BUILDING SYSTEM MANUFACTURER – 2nd ICE RINK

Behlen Industries 204-728-1188

STEEL BUILDING SUPPLIER

Colony Management Inc. 604-688-2604

PHOTOGRAPHER

Matthew Halverson 604-873-7848

DESIGN AND CONSTRUCTION TEAM - VANDERHOOF AQUATIC CENTRE:

ARCHITECT

Carscadden Stokes McDonald Architects Inc. 604-633-1830

STRUCTURAL ENGINEERS

CWMM Consulting Engineers Ltd. 604-731-6584

GENERAL CONTRACTOR

Grayback Construction Ltd. 250-493-7972

STRUCTURAL STEEL SUPPLIER

North Arm Machine Ltd. 604-526-2673

STEEL ROOF DECK SUPPLIER

North Arm Machine Ltd. 604-526-2673

STEEL ROOF CLADDING SUPPLIER

Westform Metals 604-858-7134

STEEL ROOF CLADDING INSTALLER

Admiral Roofing & Wall Systems Ltd. 250-561-1230

PHOTOGRAPHER

Armen Mamourian 604-633-1830

SPECS:

TERRACE SPORTSPLEX:

Dark Red 56064 and unpainted Galvalume AZM180.

TERRACE AQUATIC CENTRE – FITNESS ROOM

Cladding – .61mm (.0239”) 1.2mm (1⁄2”) corrugated AZM180 Galvalume.

TERRACE 2nd ARENA – FRAMELESS CONVEX STEEL BUILDING SYSTEM

UNPAINTED CLADDING:

.61mm (.0239”) AZM 180 Galvalume horizontal cladding, Ultra Span profile.

PRE-PAINTED CLADDING:

1.22mm (.048”) AZM 180 Galvalume coated steel cladding, coloured Black, CS75 panel.

ROOF PANEL:

Unpainted Z275 (G90) CS75 panel.

VANDERHOOF AQUATIC CENTRE

STEEL ROOF DECK:

Z275 (G90) galvanized

STRUCTURAL FRAMING:

Wide flange beams, steel trusses, HSS sections and pipe sections were used in the framing of the building.

ROOF CLADDING:

AR5150-NS 38mm (1.5”) Snap Lock hidden fastener roof panel, Z275 (G90) galvanized.